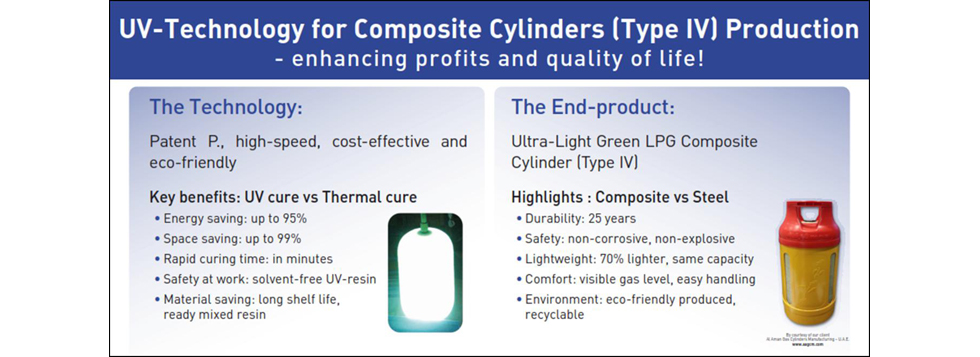

Our new activity since 2010 is the development of a cost effective and eco-friendly LPG composite cylinder (TYPE IV) manufacturing line through replacing outdated thermal curing systems with futureproof UV-technology (international patents pending).

Composite LPG cylinders Type IV, consisting of glass fibre reinforced plastic liner (patent p.), boss (patent p.), pressure valve and plastic casing offer a lot of advantages in comparison with steel cylinders:

Maximum Safety

- No explosion risk under fire or bullet shot, suitable for domestic, leisure or industrial use

- Designed to meet European and international standards

- No rust

Comfort

- Gas level is always visible thanks to translucent properties

- Convenient handling stacking and cleaning due to ergonomic design

- Modern, customizable design with attractive branding opportunities on the cylinder casing

Lightweight *

- Up to 70% weight reduction with same tank capacity

Environmental friendly

- Recyclable

- Reduced logistics and maintinance costs *

All these properties together with the attractive and modern design assure LPG composite cylinders a great worldwide market acceptance and potential.

Composite LPG cylinders (thermally cured) are already successfully used in many countries.

COIA provides 1st LPG Composite Cylinders Manufacturing Plant to the UAE

The United Arab Emirates will soon have their first manufacturing plant for LPG composite cylinders. COIA Germany has just closed a deal with AL AMAN Gas Cylinders Manufacturing LLC, Sharjah for a turn-key project to produce a total of 1 Mio. cylinders/year and will supply design, technology, state-of-the-art machines, raw materials and equipment.